When it comes to SS screws, knowing the difference between rolled threads and cut threads is crucial for ensuring optimal performance and longevity in various applications. With the global fastener market expected to reach $114.8 billion by 2025, it’s more important than ever to make informed decisions when selecting the right type of thread for your projects. In this blog post, we’ll dive deep into the world of rolled threads and cut threads, exploring their unique manufacturing processes, advantages, and applications.

Screw threads have a fascinating history that dates back to ancient times. The earliest known screw threads were used in wine and olive oil presses in ancient Greece, while the first screw-cutting lathe was invented by the Englishman Henry Maudslay in 1797. As technology progressed, the manufacturing processes for creating screw threads evolved, leading to the development of rolled threads and cut threads. Thus learning more about the difference between rolled threads and cut threads in ss screw, helps us pick the most suited screws for the application.

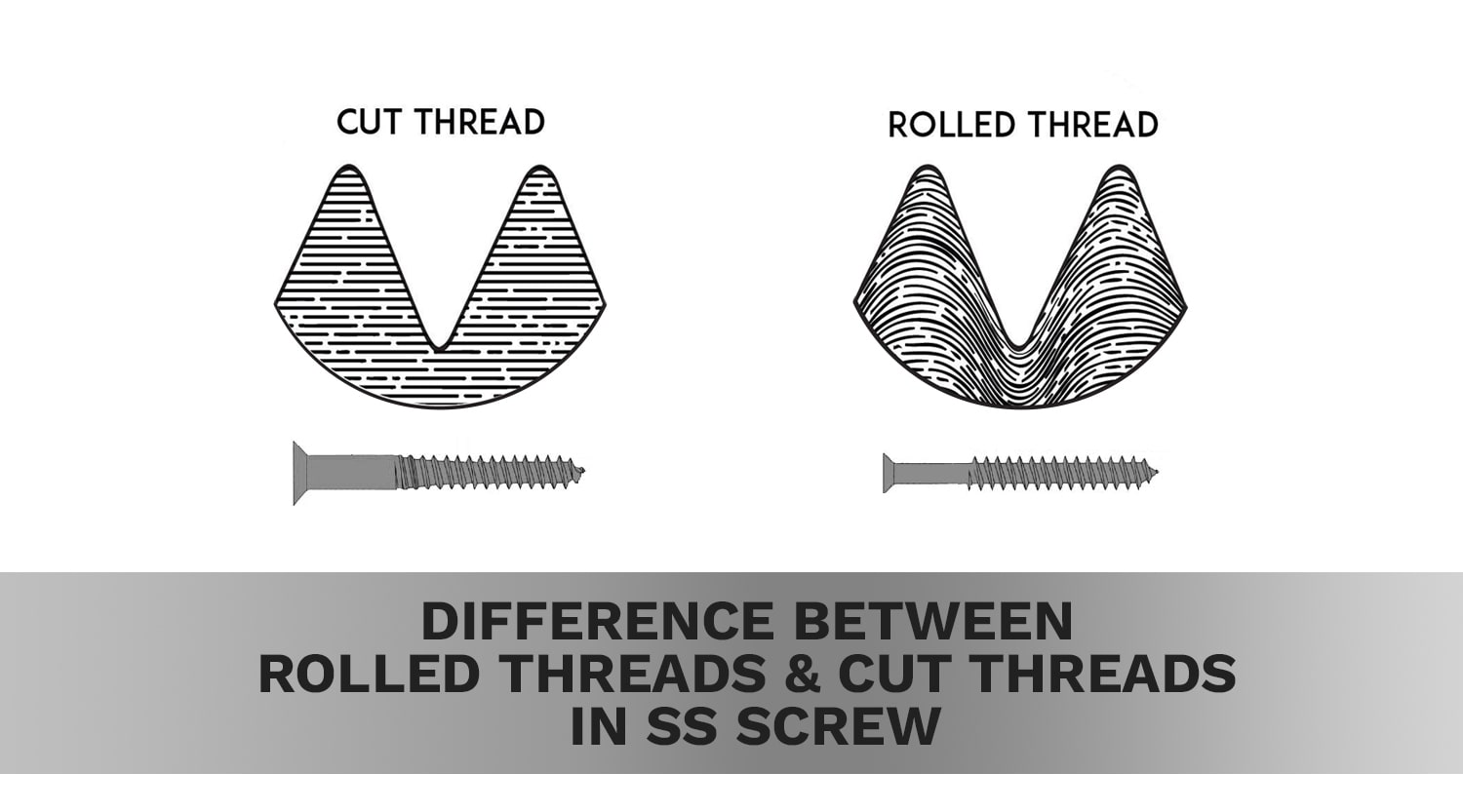

Rolled threads are created through a process of metal deformation, where a blank stainless steel rod is passed through a set of dies bearing the desired thread profile. As the rod is compressed and shaped, the threads emerge without any material removal. This cold-working process not only forms the threads but also enhances the screw’s mechanical properties, resulting in superior strength and durability.

In contrast to rolled threads, cut threads are created by removing material from the stainless steel rod using specialised cutting tools. This process involves making successive passes with tools such as single-point threading tools, taps or dies until the desired thread profile is achieved.

Once we know the difference between rolled threads and cut threads in ss screw, several factors need to be taken into account. These include the specific application requirements, desired strength and durability, production volume, and material properties.

Rolled threads are the preferred choice for high-volume production and applications that demand superior strength and fatigue resistance. They are commonly used in automotive, aerospace, and construction industries, where reliability and performance are paramount.

On the other hand, cut threads offer versatility and customization options, making them suitable for specialised applications, prototyping, and low-volume production. They are often used in medical devices, instrumentation, and precision machinery, where specific thread profiles and tight tolerances are required.

In many cases, rolled threads and cut threads can be used interchangeably. However, it’s essential to consider the specific application requirements, such as strength, precision, and material compatibility, when making the decision.

Rolled threads are generally more economical for high-volume production due to faster production rates and minimal waste generation. The rolling process enables efficient and high-volume manufacturing of stainless steel screws, making it the preferred choice for cost-effective production.

Some materials, particularly those that are brittle or have low ductility, may not be suitable for the rolling process. These materials may crack or fail during the deformation process, thus making cut threads an appropriate choice.

The corrosion resistance of SS screws is primarily determined by the grade of stainless steel used. However, the smooth surface finish of rolled threads may provide a slight advantage in terms of corrosion resistance compared to cut threads.

Understanding the difference between rolled threads and cut threads is extremely vital for anyone working with stainless steel screws. By weighing the advantages and limitations of each thread type, you can make informed decisions that optimise the performance, durability, and cost-effectiveness of your projects.

At LP Screw, we are dedicated to providing our customers with high-quality stainless steel screws and the knowledge to support their success. Whether you are a professional tradesperson, a DIY enthusiast, or an industrial manufacturer, our extensive range of rolled thread and cut thread stainless steel screws is designed to meet your diverse needs.

As a trusted Indian screw manufacturing brand, LP Screw is committed to delivering precision, reliability, and excellence in every product we offer. Our team of experts is always ready to assist you in selecting the right thread type for your specific application, ensuring that you achieve the best possible results.

In conclusion, by understanding the intricacies of rolled threads and cut threads in SS screws, you can make informed choices that enhance the strength, durability, and performance of your projects. Trust LP Screw to be your partner in providing superior fastening solutions that exceed your expectations.