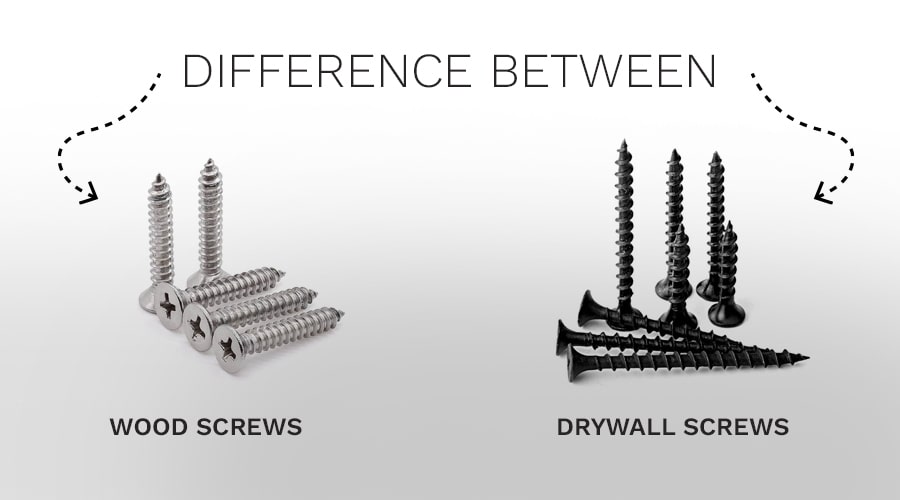

In the realm of construction and woodworking, the choice of screws can significantly impact the integrity and longevity of a project. Two commonly used screws- wood screws and drywall screws, serve distinct purposes owing to their unique designs and applications. In this blog, we will delve into the difference between wood screws and drywall screws, shedding light on the crucial distinctions.

Wood screws, as the name suggests, are tailored for woodworking and carpentry applications, excelling in providing a robust and lasting connection between wooden elements. The key characteristics that set wood screws apart are:

Thread Design: Wood screws boast deep and coarse threads, optimizing their ability to grip wood fibers securely. This design ensures exceptional holding power, preventing the screw from loosening over time and contributing to the structural integrity of the wood.

Point Styles: Various point styles cater to specific woodworking needs. Sharp points are ideal for general woodworking, flat points are for applications involving hinges, and gimlet points are easier to penetrate wood.

Materials and Coatings: Typically crafted from steel, wood screws often undergo coatings to enhance corrosion resistance. Stainless steel wood screws, in particular, are a popular choice for outdoor applications due to their superior resistance to rust and corrosion.

Head Styles: Wood screws come in an array of head styles, including flat heads, oval heads, and round heads. The choice of head style is often decided by aesthetic preferences and functional requirements for the particular project.

Drywall screws, designed specifically for attaching drywall to framing or other wall materials, serve a different purpose than wood screws. Precision and finesse are crucial in drywall installation, and these screws are tailored accordingly:

Thread Design: Featuring fine threads, drywall screws efficiently grip the drywall without causing damage to its delicate surface. The fine threads allow quick penetration without tearing, making them suitable for the thin and fragile drywall material.

Point Styles: Drywall screws are equipped with sharp points designed for swift penetration through drywall, ensuring ease of installation without causing excessive damage to the material.

Materials and Coatings: Similar to wood screws, drywall screws are predominantly made from steel. Coatings such as phosphate or black oxide are common choices, providing corrosion resistance and reducing friction during installation.

Head Styles: The heads of drywall screws are typically bugle-shaped or flat, designed to sit flush with the drywall’s surface without damaging the paper covering. This ensures a smooth and seamless look of the final product.

Corrosion Resistance: While wood screws and drywall screws have their specific applications, the choice of material can enhance their overall performance. Stainless steel screws by LP screws, known for their exceptional corrosion resistance, are becoming increasingly popular in both wood and drywall applications. The corrosive nature of wood preservatives or the moisture-prone environment of bathrooms and kitchens makes stainless steel screws an excellent choice for longevity and durability.

Versatility: Stainless steel screws transcend the boundaries of traditional wood and drywall applications. Their resistance to rust and corrosion makes them suitable for outdoor projects, coastal regions, or any environment where exposure to the elements is a concern. As a result, they serve as a versatile option, providing reliability across a spectrum of fastening needs.

Aesthetics: In addition to their functional benefits, stainless steel screws contribute to the aesthetic appeal of the finished project. Their sleek and polished appearance adds a touch of modernity and professionalism, making them an attractive choice for visible fastening in both woodworking and drywall installations.

The difference between wood screws and drywall screws boils down to understanding the unique requirements of the project at hand. Here are some key considerations to guide your choice:

Material Compatibility: Consider the material you are working with. If your project involves wood, opt for wood screws with a thread pattern designed for gripping wood fibers. For drywall installations, choose screws with a fine thread and a bugle-shaped head to prevent damage to the delicate material.

Project Scope: Evaluate the scale and nature of your project. If you’re undertaking a woodworking project, wood screws are tailored for the job. Conversely, for tasks involving the installation of drywall, drywall screws with self-drilling capabilities are a more efficient choice.

Environmental Factors: Assess the environmental conditions to which the fasteners will be exposed. In outdoor or moisture-prone settings, stainless steel screws can provide the necessary corrosion resistance, ensuring the longevity of the connection.

Appearance: Consider the visibility of the fasteners in the finished project. If aesthetics are a priority, stainless steel screws can offer a polished, modern look that complements various design styles.

In the expansive landscape of construction and woodworking, the unsung heroes are the screws that hold it all together. The difference between Wood screws and drywall screws is important to know as each plays a vital role in ensuring the success and longevity of your projects. Whether you are framing walls, installing drywall, or crafting intricate woodworking designs, the right screw is the linchpin that ensures your work stands the test of time.