Did you know that the Saturn V rocket, which propelled humans to the Moon, used over 3 million fasteners? That’s right – the journey that took mankind to another celestial body relied on millions of nuts, bolts and other fasteners to keep everything together during its incredible journey.

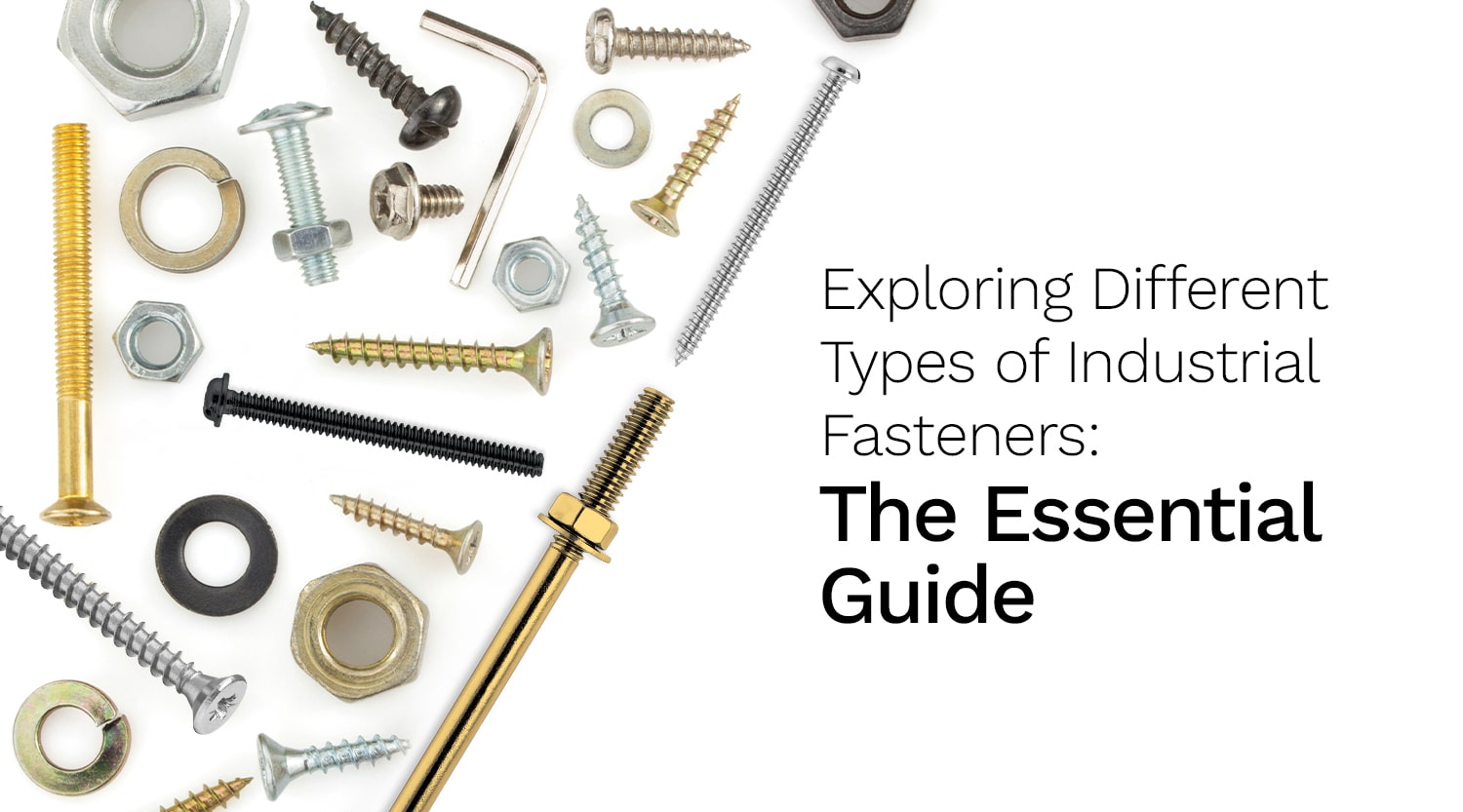

When it comes to manufacturing and construction, the importance of industrial fasteners cannot be overstated. These small components play a crucial role in holding together everything from massive structures to intricate machinery. In this comprehensive guide, we’ll explore the various types of industrial fasteners, their applications, and why choosing the right fastener is critical for any project.

Industrial fasteners are mechanical devices designed to join two or more objects together. They come in a wide variety of shapes, sizes, and materials, each tailored to specific applications. From the simple screw to complex specialized bolts, fasteners are the unsung heroes of the manufacturing world.

1. Screws: Screws are perhaps the most common type of industrial fasteners. They feature a threaded shaft and a head designed for various tools. Some popular types include:

2. Bolts: Bolts are similar to screws but are typically larger and used with nuts to create a secure fastening. Common bolt types include:

3. Nuts: Nuts are the counterparts to bolts, featuring internal threads that match the bolt’s external threads. Popular nut types are:

4. Washers While not fasteners themselves, washers are crucial components used with bolts and screws. They distribute load and prevent damage to the joined materials. Types include:

5. Rivets Rivets are permanent fasteners used in applications where access is limited to one side of the joint. Common types are:

6. Pins Pins are used for alignment, pivoting, or shear applications. Some common pin types include:

Stainless steel (SS) fasteners deserve special mention due to their exceptional properties. These fasteners offer superior corrosion resistance, making them ideal for applications in harsh environments or where hygiene is paramount. Industries such as food processing, chemical manufacturing, and marine engineering heavily rely on SS fasteners.

Selecting the appropriate fastener for your project is crucial. Here are some factors to consider:

1. Material: The fastener’s material should be compatible with the joined materials and suitable for the environment.

2. Load requirements: Consider the weight and forces the fastener will need to withstand.

3. Environmental factors: Temperature, humidity, and exposure to chemicals can affect fastener performance.

4. Assembly and disassembly needs: Some fasteners are permanent, while others allow for easy removal.

5. Cost: Balance the need for quality with budget constraints.

India has emerged as a significant player in the global fastener market, with many reputable stainless steel fasteners manufacturers producing high-quality products. These manufacturers offer a wide range of SS fasteners, catering to diverse industrial needs. When choosing a supplier, look for certifications, quality control processes, and a track record of reliable service.

While screws, nuts, and bolts are the most recognized industrial fasteners, the category extends far beyond these basics. Here are some specialized fasteners you might encounter:

As manufacturing technologies evolve, so do fasteners. Innovations in materials science and design are leading to stronger, lighter, and more versatile fastening solutions. Some exciting developments include:

Conclusion

Industrial fasteners may seem like simple components, but they play a vital role in countless applications. From the SS fasteners ensuring hygiene in food processing plants to the heavy-duty bolts holding together skyscrapers, these unassuming pieces of hardware are essential to our modern world. Whether you’re a manufacturer, engineer, or DIY enthusiast, understanding the different types of industrial fasteners and their applications is crucial. By choosing the right fastener for the job, you ensure the safety, efficiency, and longevity of your projects.

At LP Screw, we’re not just a leading stainless steel fasteners manufacturer in India, we’re passionate about sharing our knowledge, which is why we keep sharing insightful articles like this one. Following us on our social media channels is a great way to ensure that you never miss an update. So do consider following us on our social media handles. We will soon meet with yet another article. Stay tuned!