When it comes to fastening solutions, the smallest details often have the most significant impact. Have you ever noticed how some screws rust, lose their Colour, or fail to withstand wear and tear? The quality of screws can make or break a product’s longevity and aesthetics, whether you’re working on intricate watch assemblies or constructing a building facade. Enter LP Screw’s latest innovation: PVD finishing SS screws. This game-changing technology ensures that your screws are not just durable but also aesthetically pleasing, making them perfect for any application, from delicate watch assemblies to robust building facades. Let’s dive deeper into what makes PVD finishing SS screws a must-have in your toolkit.

Physical Vapor Deposition (PVD) coating is a cutting-edge technology that involves the deposition of a thin metallic film onto screws. Unlike traditional coating methods like painting or anodizing, PVD coating provides a range of benefits that enhance both the function and form of screws. But what exactly is PVD coating, and why is it becoming the preferred choice for manufacturers and consumers alike?

PVD coating is a vacuum deposition process where the desired coating material, often a metal, is vaporized in a vacuum chamber and then deposited onto the screws. This process not only adds a layer of protection but also gives the screws a decorative finish that is highly resistant to wear and tear. The result is a PVD finishing SS screw that is stronger, more durable, and more visually appealing than its traditionally coated counterparts.

To understand why PVD finishing SS screws are so effective, it’s important to look at the science behind the coating process. During PVD coating, the metal vapor condenses on the substrate, forming a thin film that adheres tightly to the surface. This film is not only hard but also incredibly smooth, reducing friction and enhancing the screw’s ability to withstand wear and tear.

Moreover, the vacuum environment in which the PVD coating process takes place ensures that the screws are free from impurities that could compromise their quality. This high level of purity means that PVD coating stainless steel screws are not only resistant to corrosion but also maintain their appearance over time, making them ideal for applications where both functionality and aesthetics are important.

With so many options on the market, you might wonder what makes PVD finishing SS screws stand out from the rest. Here are some compelling reasons why they are the top choice for anyone looking to invest in high-quality fastening solutions:

PVD finishing SS screws are designed to last. The PVD coating process adds a layer of protection against corrosion, wear, and environmental factors. This ensures that your screws remain intact and perform optimally, even in challenging environments such as coastal areas, industrial settings, or places with extreme weather conditions. Whether you’re a stainless steel screw manufacturer or an end-user, you can rely on these screws to maintain their integrity over time.

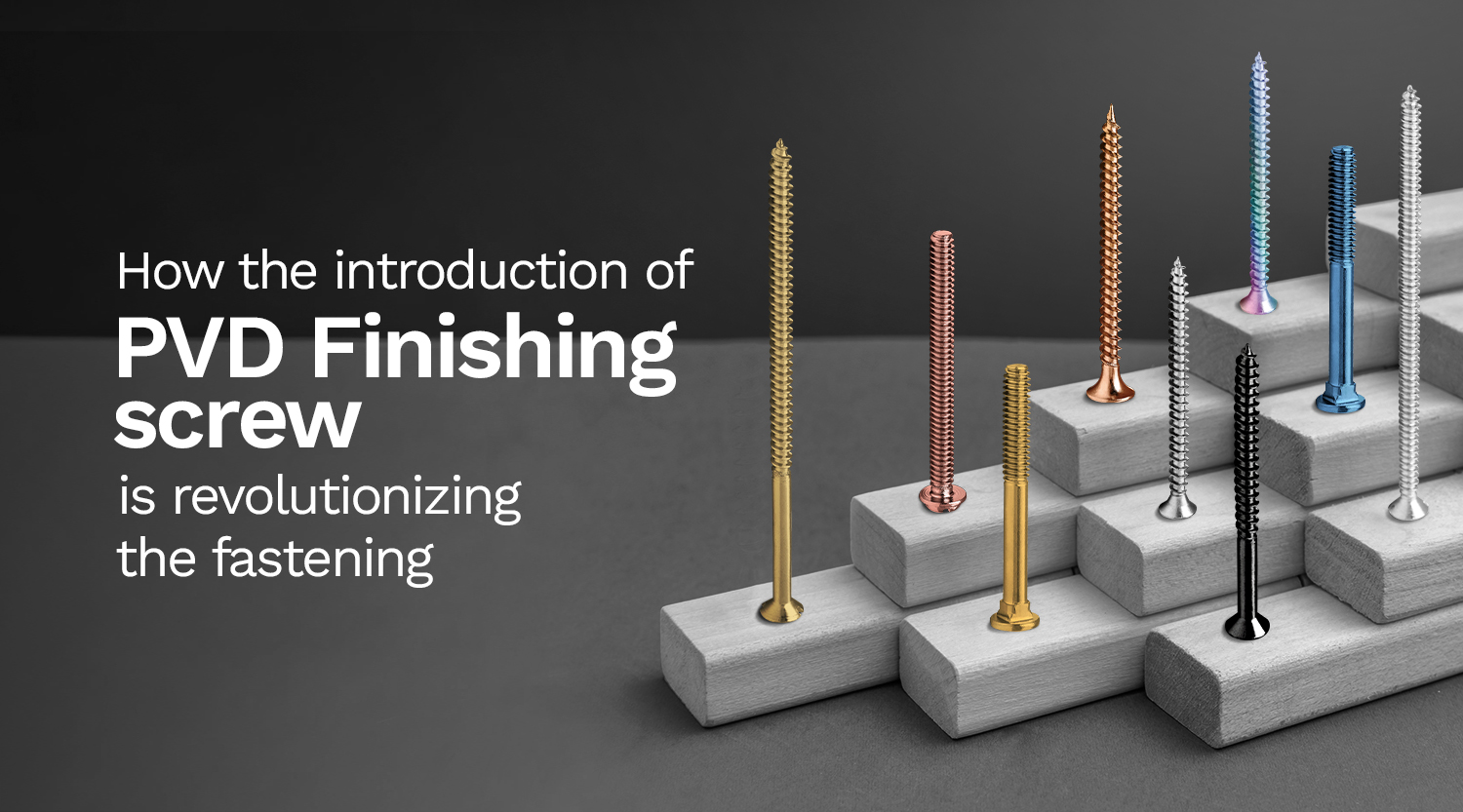

One of the unique selling points of PVD finishing is its ability to deliver consistent colour across different batches of screws. Whether you’re looking for a black screw, gold screw, or even a rainbow finish, PVD coating ensures that each screw has a uniform appearance. This is especially crucial for applications where aesthetics matter as much as durability, such as in interior design, luxury goods manufacturing, and architectural projects. The consistent Colour also means that you can replace screws or add new ones without worrying about mismatched hues.

View this post on Instagram

Unlike anodized screws, which can fade under sunlight or become blemished with oils and greases, PVD-coated screws maintain their appearance and performance. The non-porous nature of the PVD coating means that the screws are resistant to external factors that commonly affect other types of finishes. This makes PVD finishing SS screws ideal for outdoor applications, such as decking, fencing, and even marine environments, where exposure to elements is a constant concern.

The versatility of PVD coating technology is another reason why it is favored by manufacturers across various industries. PVD-coated screws are used in a wide range of applications, from the smallest screws used in watchmaking to the larger screws that hold together the panels of a building facade. This technology ensures that the same Colour shade is achieved on screws, plates, and accessories, creating a harmonious look in any application. For industries like automotive, aerospace, and electronics, where both precision and aesthetic appeal are crucial, PVD COATING STAINLESS STEEL SCREWS offer a perfect solution.

While PVD-coated screws may come at a slightly higher upfront cost than their non-coated counterparts, they are a more cost-effective choice in the long run. The enhanced durability and corrosion resistance mean fewer replacements and repairs over time, which translates to lower maintenance costs. Additionally, the consistent Colour quality reduces the need for frequent replacements due to aesthetic concerns, making PVD finishing SS screws a smart investment for businesses looking to cut costs without compromising on quality.

For those still on the fence about choosing PVD-coated screws, a comparative analysis with anodized screws can provide further clarity. Anodizing, a popular coating method for metals, involves electrochemical processes that add a decorative finish and some corrosion resistance. However, anodized screws have several drawbacks that PVD-coated screws effectively address:

Anodizing requires acid etching bolts, making the surface porous to allow Colour refracting. This process can weaken the screw, reducing its strength and stretch resistance. In contrast, PVD coating does not compromise the structural integrity of the screw, maintaining its original strength and functionality.

Anodized finishes can vary from batch to batch due to factors like room temperature, water temperature, and electrolyte dilution levels. This inconsistency can lead to mismatched screws in applications where uniform appearance is critical. PVD-coated screws, on the other hand, offer consistent Colour across different batches, ensuring a uniform look and feel.

Anodized screws are prone to fading when exposed to sunlight and can develop blemishes from oils and greases. PVD-coated screws, however, are resistant to these factors, maintaining their appearance and performance over time.

A: PVD finishing SS screws provide consistent Colour quality, are more resistant to corrosion and wear, and do not fade or get blemished over time, unlike anodized screws. This makes them a superior choice for both aesthetic and functional applications.

A: Yes, PVD-coated screws are highly resistant to environmental factors, making them perfect for both indoor and outdoor applications. Their resistance to corrosion and wear ensures they remain intact and visually appealing, even in harsh conditions.

A: Absolutely! PVD coating can produce a range of Colours, including black, gold, rainbow, and copper, ensuring that there’s a perfect match for every aesthetic requirement. This versatility makes PVD-coated screws a popular choice for both functional and decorative purposes.

A: PVD coating enhances the performance of stainless steel screws by providing a hard, smooth surface that reduces friction and increases resistance to wear and corrosion. This makes them ideal for high-stress environments where durability and reliability are paramount.

As a leading stainless steel screw manufacturer, LP Screw is proud to introduce our latest product offering: PVD finishing SS screws. This innovative solution provides unmatched durability, Colour consistency, and resistance to wear, making it the ideal choice for a wide range of applications. Whether you’re in construction, automotive, or any industry requiring high-quality fastening solutions, our PVD-coated screws are designed to exceed your expectations.

By choosing PVD finishing SS screws, you’re investing in a product that offers superior performance, longevity, and aesthetic appeal. Upgrade to PVD finishing SS screws today and experience the future of fastening technology with LP Screw!