Fasteners are the unsung heroes of the construction and manufacturing world. Whether you’re building a skyscraper or assembling a piece of furniture, choosing the right ss fastener is pivotal. One common decision we all face is whether to opt for coarse thread or fine thread fasteners. In this blog, we’ll explore the key similarities and differences between these two types of fasteners, their various uses, and provide guidance on when to select each type to ensure a secure and efficient connection.

Coarse thread and fine thread fasteners share several basic features or characteristics. Both types are essential for holding parts or materials together securely. They come in various shapes and sizes, including screws, bolts, and nuts, and are typically made from materials such as steel, stainless steel, or brass. Coarse and fine thread fasteners are designed to create a mechanical bond, preventing materials from separating unintentionally.

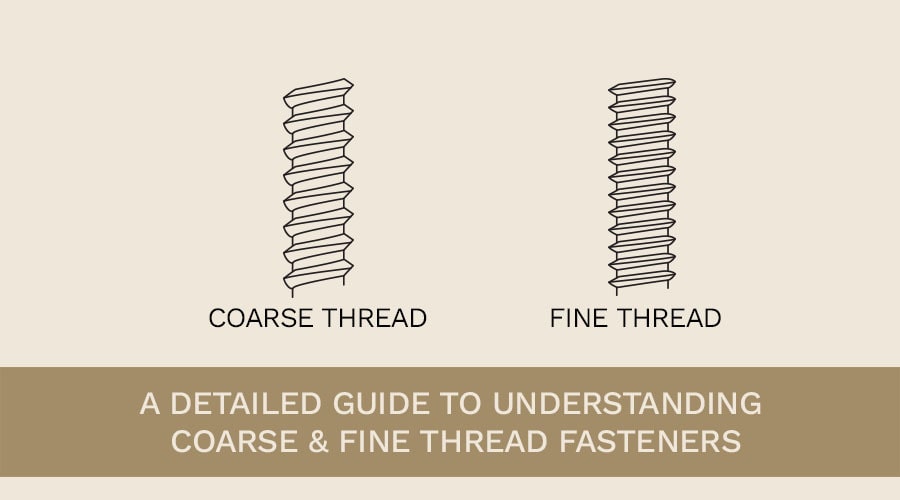

The primary distinction between coarse and fine thread fasteners lies in the thread pitch, which refers to the distance between threads. Coarse thread fasteners have a larger thread pitch, meaning fewer threads per inch. They are better suited for applications where speed and ease of installation are crucial, as the larger threads allow for quicker turning and assembly. Fine thread fasteners, on the other hand, have a smaller thread pitch, providing more threads per inch. This results in a finer and more precise adjustment, making them ideal for applications where precision and tight tolerances are required.

Coarse thread fasteners are well suited in cases where strength and speed are essential. Here are some common applications where coarse thread fasteners come handy:

1. Construction: Coarse thread screws and bolts are commonly used in construction for framing and structural connections. Their quick installation helps save time on the job site.

2. Woodworking: When fastening wood, coarse thread screws provide a secure grip, making them suitable for tasks such as building cabinets, decks, and furniture.

3. Automotive: Coarse thread screws and bolts are often used in automotive applications, such as securing engine components and chassis parts.

4. Plumbing: SS Fasteners with coarse threads are employed in plumbing installations to connect pipes and fixtures securely.

5. Outdoor Projects: Coarse thread screws are ideal for outdoor projects like fencing where they can withstand exposure to the harsh environmental conditions.

Fine thread fasteners offer precision and reliability, making them suitable for applications that require high tolerances and delicate adjustments. Here are some common scenarios where fine thread fasteners excel:

1. Aerospace: Fine thread fasteners are critical in aerospace engineering, where precision is paramount. They are used to secure critical components and ensure the safety of aircraft.

2. Electronics: Fine thread screws are essential in the assembly of delicate electronic devices, such as laptops and smartphones, where tight connections and vibration resistance are necessary.

3. Automotive Engineering: In automotive manufacturing, fine thread fasteners find their place in engine internals and other components demanding precise torque control.

4. Medical Devices: Medical equipment assembly relies on fine thread fasteners to ensure the secure and precise connection of components in devices like surgical instruments and diagnostic equipment.

5. Fine Machinery: Fine thread ss fasteners are used in the production of machinery requiring key adjustments, such as laboratory equipment and high-precision manufacturing tools.

Choosing between coarse and fine thread fasteners boils down to the specific requirements of your project. Consider the following factors:

1. Application: Determine the nature of your project. If it involves heavy-duty construction or woodworking, coarse thread fasteners may be the better choice. For precision applications like electronics or aerospace, fine thread fasteners are more suitable.

2. Load and Stress: Examine the load and stress your fasteners will endure. Coarse thread fasteners offer better shear strength, while fine thread fasteners provide enhanced tensile strength.

3. Material Compatibility: Consider the materials you are joining. Some materials may work better with coarse or fine thread fasteners due to their thread engagement and grip.

4. Torque Control: If precise torque control is necessary, fine thread fasteners allow for more accurate fastening.

Few Closing Thoughts

In the world of ss fasteners, the choice between coarse thread and fine thread can significantly impact the success of your project. Understanding their key similarities, differences, and applications is essential for making the right selection. Whether you prioritize speed or precision, choosing the appropriate fastener will ensure your connections are strong, reliable, and tailored to your project’s unique needs.

The other often overlooked aspect is that any fastener whether coarse or fine thread will perform well only when it is manufactured as per the benchmarked standards. Poor quality material will make the connection or joint lose no matter the type of fastener. In such cases it is ideal to opt for fasteners or screws from a renowned & reliable manufacturer like us at LP Screw, India’s leading stainless steel fastener manufacturer. From antique, standard & PVD finishes to offering impeccable strength & toughness LP Screw versatile offerings stand apart from the rest. Try them today and see the output speak for themselves.