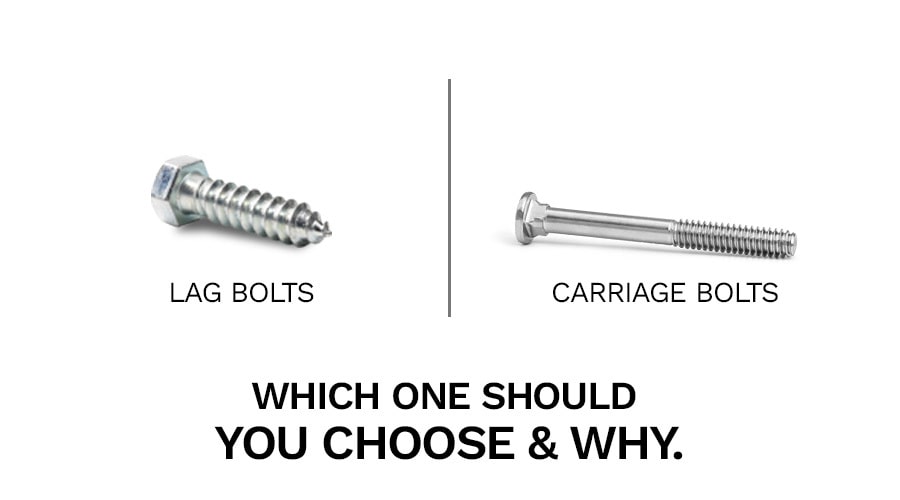

When it comes to stainless steel screws, choosing the right type for your project can make all the difference in ensuring a strong and secure connection. Lag bolts and carriage bolt screws are two commonly used fasteners, each with its unique characteristics and applications. In this blog, we will delve into the key differences between lag bolts and carriage bolts, exploring their design, uses, and the factors to consider when deciding which one to use for your specific project.

Lag bolts, also referred to as lag screws or coach screws, are heavy-duty fasteners primarily designed for wood-to-wood connections or joints. They have a thick, coarse, and partially threaded shaft with a pointed tip. The head of a lag bolt can be either hexagonal or square, allowing for easy installation with a wrench or machine.

Threading: The threading on lag bolt screws typically covers about two-thirds of the shaft’s length. This threading provides strong gripping power when driven into wood, ensuring a secure & robust joint.

Applications: Lag bolts are commonly used in construction, woodworking, and outdoor projects. They are ideal for joining heavy timber, constructing decks, fastening beams, and building fences & docks.

Load-Bearing Capacity: Lag bolts offer superior load-bearing capacity, making them suitable for heavy-duty applications and structural connections.

Shear Strength: Lag bolts offer a good amount of shear strength but not as much as carriage bolts.

Head Styles & Support: They come primarily in hexagonal & square head styles and require a wrench or socket for their fastening. They do not need any external support like that of nuts or washers.

Pilot Hole Requirement: As with all major outdoor screws, lag bolts do require a pre-drilled hole to ensure hassle-free fastening in a short amount of time.

Carriage bolt screws, also known as coach bolts, are designed for use with wood, metal, or other materials. Unlike lag bolts, carriage bolts feature a smooth, cylindrical shaft with a flat, square or round head. The head of a carriage bolt has a square shoulder, preventing it from turning when tightening the nut.

Smooth Shaft: The smooth shaft of carriage bolts allows for easy insertion into pre-drilled holes. This feature is particularly useful when you need to ensure precise alignment of the connected materials.

Applications: Carriage bolts are commonly used in applications where a smooth finish on the surface is essential. They are frequently utilized in furniture assembly, attaching metal brackets, and connecting wood-to-metal or wood-to-plastic.

Load Bearing Capacity: Carriage bolts are still strong but may not be as robust as lag bolts when it comes to handling extremely heavy loads.

Aesthetics: If appearance is crucial to your project, carriage bolt screws provide a clean and polished look, as their heads sit flush with the surface.

Shear Strength: Most carriage bolts possess a shear strength of several thousand psi and are generally far stronger than their lag screw counterparts.

Head Styles & Support: Unlike the traditional angular head style in a lag screw, carriage bolt come in circular and square head style. They need the support of washers & nuts for a safe, secure & steady fastening.

Pilot Hole Requirement: Carriage bolts undoubtedly require pre-drilled holes or pilot holes for easier fastening. This ensures that the screw are positioned correctly and are held tightly to make the joint long-lasting.

In conclusion, both lag bolts and carriage bolt screws are valuable fasteners with unique characteristics that suit different applications. Lag bolts excel in wood-to-wood connections, offering strength and durability, while carriage bolts are versatile and provide a neat finish for a wide range of materials.

When choosing between lag bolts and carriage bolts, consider the specific requirements of your project, load-bearing needs, and the desired aesthetics. Understanding the key differences between these fasteners will empower you to make an informed decision, ensuring a successful and secure outcome for your construction or woodworking project.

The only point to be kept in mind while going for either screw is that, they should be of high quality & benchmarked against industrial standards. LP Screw, India’s trusted leader in SS & MS screw manufacturing offer over a dozen options to our esteemed clients. With an industry experience spanning decades, our ss screws are the best bet for your unique fastening requirements.